About our first MG

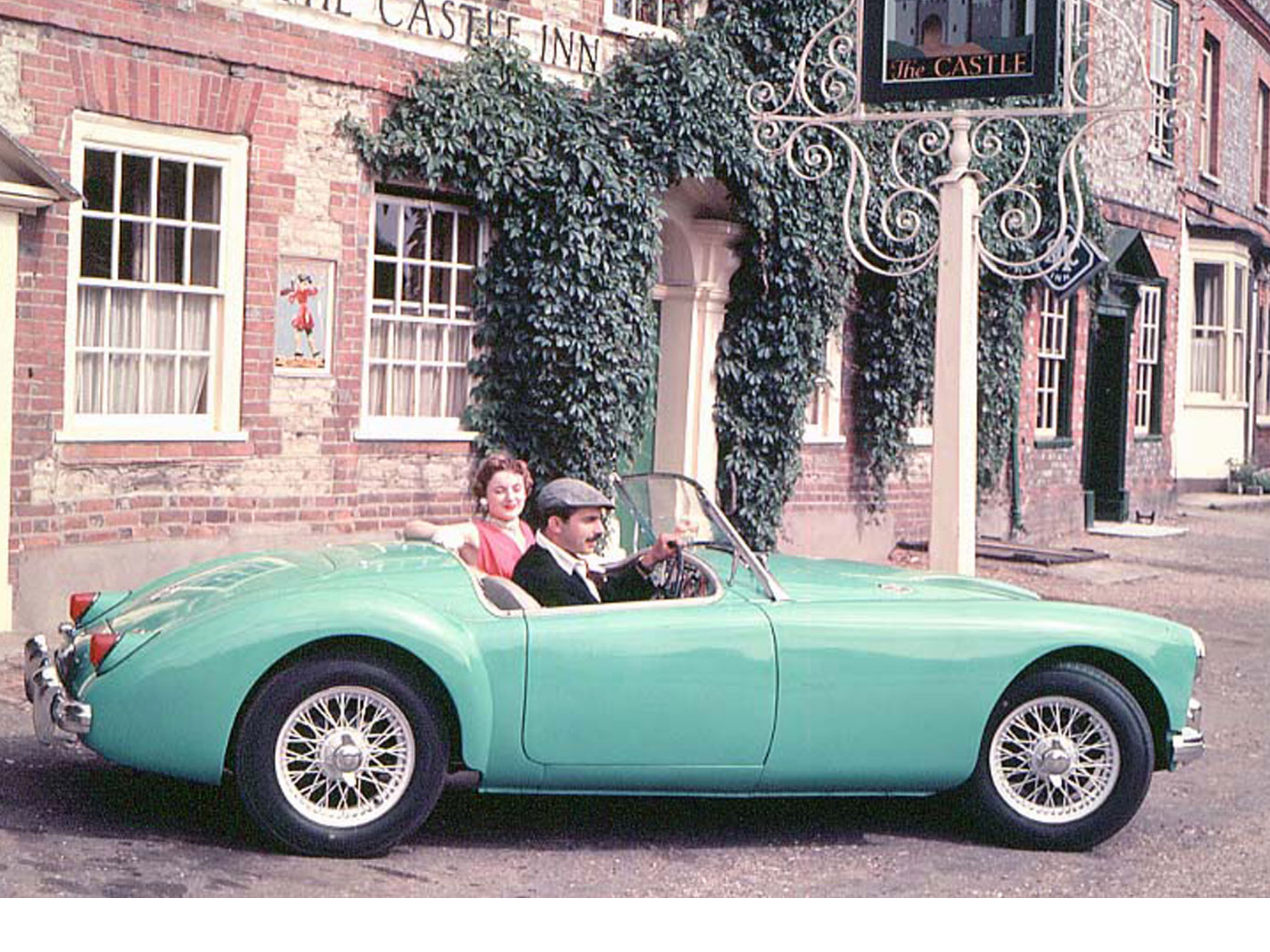

English automotive art began with an MGA, a vehicle that stands out for its wonderful curves and sportiness.

The color of this MG is Tyrolite Green (color code GN7). This color was no longer available in later versions, or more precisely, it was no longer offered.

Some MG connoisseurs doubt that our color really existed when they see our car. Here is a photo from an MG catalog. This photo shows an MGA 1500 TyroLite Green.

It was a coincidence that my wife found this vehicle. Her father wanted to go to an auction in Salzburg. He has already sold several cars there himself.

He came to us with the catalog in his hand and asked if we wanted a ride. We initially had no ambition to accompany him.

He left the auction catalog with us and my wife leafed through the little booklet. That evening she said to me that she had seen a beautiful car.

“The shape and color are beautiful and it’s being auctioned off,” my wife said to me.

So we went to Salzburg after all and hoped for our luck. In the end, there were only two interested bidders. Us and someone on the phone. Our self-imposed budget was almost used up.

Fortunately, in the end there were no more telephone bids and we were awarded the contract.

When we brought the vehicle home, there was a certain maintenance backlog, which we cleared.

The vehicle was meticulously inspected, as the previous owner had barely documented the maintenance work and had not carried it out himself.

The workshop he regularly commissioned did not want to make a clear statement. So off we went with the inspection. We quickly realized that we needed more information and bought a lot of specialist literature.

Then we had to get some imperial tools. Up to now, we have always dealt with metric measurements.

Now things progressed meticulously step by step. Where were the loose screws or rusted connections? Other necessary activities were carried out:

- Change all fluids and oils incl. Filter

- Clean and overhaul carburetor

- Replace air filter

- Motor endoscopy

- Compression test and pressure loss test

- Wheel suspensions

- Brakes

- Battery test

- Electronic connections

- Control Box adjustment

- Dynamo testing

- …

It took about 4 months to check everything and replace the most necessary parts. The underbody and frame were then treated with plenty of “grease”. Every corner and every cavity was sprayed out.

We have carefully noted down all the work on the vehicle. Old parts that were no longer ideal were replaced and neatly packed in boxes. Who knows when you’ll need them again?

The list got longer and longer. Small errors here and there now appeared.

How good that our garage is a bit bigger and that we have an old stock of important tools and machines. So we were able to carry out all the work ourselves.

As we had little experience with English cars, we bought a lot of books and joined MG clubs to learn more about the car and the brand.

My family was annoyed at first when we kept receiving book deliveries from England or the USA. I was surprised at how many books there were about the MGA.

Lots to read, which is a welcome change from the otherwise monotonous television program in the winter months. We also found good YouTube channels and websites on the subject of MGA/MGB.

In the evening we read and the next day we heated up the garage to work on the vehicle. Step by step, centimeter by centimeter, the vehicle was checked.

Unfortunately not every day, because you also have to go about your normal work. If only you had a little more time in life.

We had set ourselves a maximum budget of around €5,000 for spare parts. If you search, you will find suppliers who deliver good, but also inexpensive spare parts. The forum of the MGDC Club is a special help.

This meant that we did not exceed the budget and were able to carry out all the necessary work.

We also didn’t want to use metric screws and bought whole sets of UNC and UNF screws and nuts in different sizes. Here, too, we found enormous differences in quality depending on the supplier.

“If we’re going to use imperial, then use imperial throughout,” was our credo. In fact, we also found metric bolts on the vehicle during the inspection, which we replaced. Hopefully we have found them all.

Because I find it difficult when working on the vehicle if you have to change the tool so that the unit of measurement is correct. We still don’t know who created this mix.

After all the work, we went to the technical inspection. First of all, I called the local test centers to find an inspector who was familiar with MG. Then I asked the inspector to take a close look at everything.

It is better to fail the test once than to have a technical defect that we have overlooked, is my motto. The test engineer approached the matter with passion. You could tell that he loves and understands classic cars.

The conclusion was that he actually found some minor issues that were documented, but in the end the inspection sticker was issued.

We rectified the minor defects immediately.

Since the wonderful vehicle has been in our hands, we have kept a record of all the work carried out. May it help the future owners (one day I too will have to leave this world).

Finally, I have to say that I have felt and still feel a lot of joy when I am working on the car. It’s simply fun.